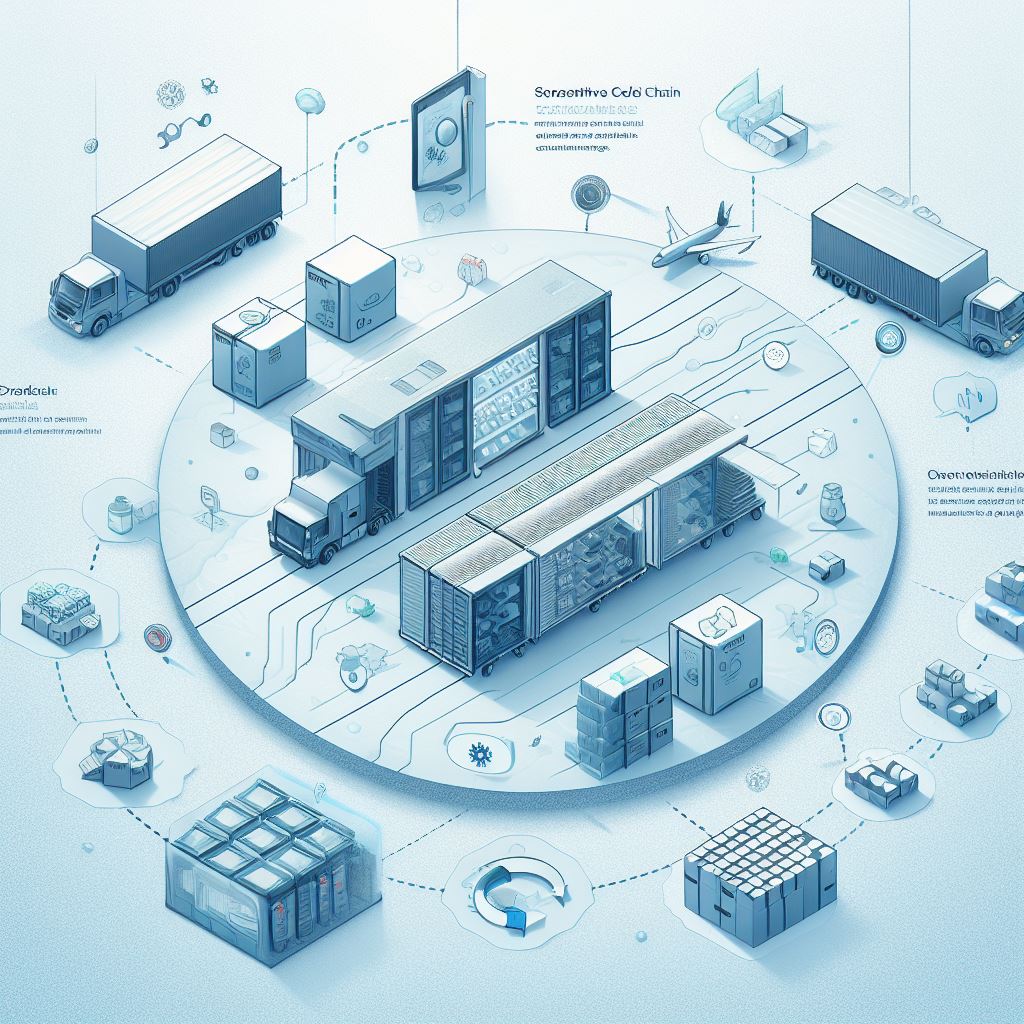

Have you ever wondered how we ensure the freshness of temperature-sensitive goods during container shipping?

Well, let me introduce you to the game-changer in cold chain management: data loggers.

As a professional in the industry, I have seen firsthand the challenges of maintaining quality throughout transportation. Data loggers revolutionize the process with continuous and accurate temperature monitoring, eliminating human error and ensuring compliance with industry standards.

In this article, we will delve into how data loggers are transforming container shipping and revolutionizing freshness preservation.

The Importance of Cold Chain Management

One crucial aspect of container shipping is the management of the cold chain, which involves ensuring the freshness and safety of temperature-sensitive goods during transportation.

Temperature control plays a vital role in cold chain management as it directly impacts the quality and shelf life of perishable goods. Temperature variations can have a detrimental effect on these goods, leading to spoilage and a loss in quality.

Maintaining the optimal temperature range is crucial to prevent such issues and ensure the integrity of the cold chain. Deviations from the desired temperature can result in financial losses for businesses.

Therefore, effective cold chain management requires precise temperature control at every stage, from production to delivery, to safeguard the quality and freshness of temperature-sensitive goods.

Limitations of Manual Temperature Monitoring

Manual temperature monitoring in container shipping has several limitations that can compromise the effectiveness of cold chain management. These limitations include:

- Human error: Manual temperature monitoring is prone to errors and inconsistencies due to human factors such as forgetfulness or negligence. This can lead to inaccurate temperature readings and potential spoilage of perishable goods.

- Limited frequency: Manual monitoring typically involves periodic checks, which means that temperature data is only captured at certain intervals. This can result in a lack of real-time visibility into temperature variations, making it difficult to identify and address temperature deviations promptly.

- Inefficient data management: Manual temperature monitoring requires manual recording and storage of temperature data, which can be time-consuming and prone to errors. It also makes it challenging to analyze and track temperature trends over time.

- Compliance challenges: Manual monitoring may not meet the stringent regulatory requirements for cold chain management. It can be difficult to demonstrate compliance with temperature control standards without accurate and reliable temperature data.

Overcoming these limitations is crucial for implementing effective cold chain management and ensuring the freshness and quality of temperature-sensitive goods during container shipping.

The Role of Data Loggers in Cold Chain Management

Data loggers play a crucial role in ensuring the freshness and quality of temperature-sensitive goods during container shipping.

With advanced data logger technology, precise temperature control is achieved throughout the cold chain management process.

By continuously monitoring temperature conditions within containers, data loggers provide real-time insights and eliminate human error that was common with manual temperature monitoring methods.

These data loggers fulfill industry regulations and certifications, such as FDA standards, ensuring compliance in cold chain management.

Key features include temperature monitoring, data storage for analysis and verification, and instant alerts for temperature breaches.

The use of data loggers enhances efficiency, reduces costs by minimizing spoilage, mitigates legal and reputational risks, and facilitates digital transformation in container shipping operations.

Proper placement, calibration, and integration of data loggers ensure reliable temperature monitoring throughout the journey.

Key Features of Data Loggers for Container Shipping

I rely on data loggers to ensure freshness and quality in container shipping by monitoring temperature conditions throughout the journey. Data loggers for container shipping come in different types, each with its own benefits. These include:

- Single-use data loggers: These are cost-effective options that are suitable for one-time use. They’re easy to deploy and provide accurate temperature monitoring during the shipment.

- Reusable data loggers: These loggers can be used multiple times and are ideal for long-term monitoring. They offer flexibility and cost savings in the long run.

- Wireless data loggers: These loggers eliminate the need for physical retrieval and provide real-time temperature updates. They offer convenience and enable proactive measures to maintain temperature conditions.

- Data logger accuracy: Data loggers ensure precise temperature monitoring, with some models offering high accuracy levels of ±0.5°C. This accuracy is crucial in maintaining the integrity of perishable goods throughout the shipping process.

Benefits of Using Data Loggers in Cold Chain Management

By utilizing different types of data loggers, container shipping operations can significantly benefit from improved cold chain management. Data loggers play a crucial role in ensuring the quality and freshness of temperature-sensitive goods throughout the supply chain logistics.

The impact of data loggers on product quality is substantial. With continuous temperature monitoring, data loggers help maintain ideal temperature conditions, minimizing spoilage and product losses. This not only enhances efficiency but also leads to significant cost savings.

By automating temperature monitoring and record-keeping tasks, data loggers streamline operations and mitigate legal and reputational risks by ensuring compliance with regulatory standards. Moreover, data loggers facilitate digital transformation, enabling proactive measures to maintain optimal temperature conditions and improve overall operational flow in container shipping.

Their benefits make data loggers an indispensable tool in cold chain management.

Integration of Data Loggers Into Container Shipping Operations

One important aspect to consider when integrating data loggers into container shipping operations is ensuring proper placement and secure installation within the containers. This is crucial to ensure accurate temperature readings and to prevent any movement or damage during transit.

To achieve this, the following steps should be taken:

- Determine the optimal placement: The data loggers should be strategically placed within the container to capture temperature variations and ensure representative readings.

- Secure installation: The data loggers should be securely installed using mounting brackets or adhesive tapes to prevent any movement or displacement during transportation.

- Calibration and maintenance: Regular calibration of data loggers is essential to ensure accurate temperature monitoring. This involves verifying and adjusting the readings against a known reference. Additionally, routine maintenance checks should be conducted to ensure the proper functioning of the data loggers.

- Integration and synchronization: Data loggers should be integrated into the container shipping operations, ensuring synchronization with other systems or platforms to enable real-time monitoring and data analysis.

Proper Placement and Maintenance of Data Loggers

To ensure accurate temperature readings and prevent movement or damage during transit, data loggers should be securely installed within containers. Proper placement techniques play a crucial role in maintaining the effectiveness of data loggers in cold chain management.

The data loggers should be strategically positioned to capture the temperature conditions within the container accurately. Placing them near the center of the cargo and away from direct contact with the container walls or doors helps minimize temperature variations.

Additionally, regular maintenance of data loggers is essential for reliable temperature monitoring. Routine calibration and verification against a known reference ensure the accuracy of temperature readings.

Read More:

Transforming Supply Chains: The Key to Success

Revolutionizing Cold Chain Operations: Mastering Efficiency

Unveiling the Secrets to Perfect Perishable Compliance

Mastering Temperature Data Logging for Optimal Performance

Privacy Policy

Ensuring Freshness: How Data Loggers Revolutionize Container Shipping

I revolutionize container shipping by ensuring freshness through the use of data loggers. These innovative devices play a crucial role in maintaining the quality and integrity of temperature-sensitive goods during transportation. Here are four key ways data loggers revolutionize container shipping:

- Precise Temperature Monitoring: Data loggers continuously monitor temperature conditions within containers, ensuring that they remain within the specified range. This prevents spoilage and preserves the freshness of perishable goods.

- Compliance with Regulations: Data loggers fulfill industry standards and certifications for cold chain management, ensuring compliance with regulations such as FDA requirements. They provide accurate and verifiable temperature data for regulatory purposes.

- Use Cases in Other Industries: Data loggers aren’t limited to container shipping. They find applications in various industries, including pharmaceuticals, food and beverage, and healthcare, where maintaining freshness and quality is critical.

- Challenges in Implementation: Implementing data loggers in container shipping poses challenges such as proper placement within containers, secure installation to prevent damage, and regular calibration to ensure accurate temperature monitoring.