As someone who regularly works with temperature data logging, I know the significance of mastering this practice for peak performance.

Whether it’s in a controlled environment or with appliances, accurate temperature monitoring is vital for ensuring the safety and quality of various processes.

In this article, I’ll share key insights and best practices for effectively managing temperature data logging.

From selecting the right sample rate to calibrating temperature loggers and maintaining the monitoring system, these guidelines will help professionals excel in this critical field.

Choosing the Right Sampling Interval

To achieve optimal performance in temperature data logging, it’s crucial to select the appropriate sampling interval. The sampling frequency selection plays a significant role in determining the accuracy of temperature measurements. Several factors can affect temperature accuracy, including the rate at which data points are recorded.

It’s important to consider the environment or appliance being monitored and choose a sampling interval that reflects the likelihood of temperature fluctuations. Setting a higher frequency doesn’t necessarily guarantee higher quality data, as it can lead to excessive data points that may not be necessary.

On the other hand, a slower sample rate is more suitable for recording data across a wider range of safe storage temperatures. By carefully selecting the sampling interval, you can ensure accurate and reliable temperature data logging.

Importance of Calibration

Calibration’s importance lies in ensuring the accuracy and efficiency of the temperature data logger. By adhering to calibration standards, we can validate the temperature sensor accuracy and maintain reliable data recording.

Calibration is a critical step in the temperature monitoring process, as it verifies the performance of the temperature sensor and ensures that it operates within acceptable limits. Through calibration, any deviations or inaccuracies in temperature measurement can be identified and corrected, leading to more precise and reliable data.

Additionally, calibration helps to establish a baseline for the temperature data logger, allowing for accurate comparisons and analysis over time. By regularly calibrating the temperature data logger, we can optimize its performance and ensure the integrity of our temperature monitoring system.

Read More:

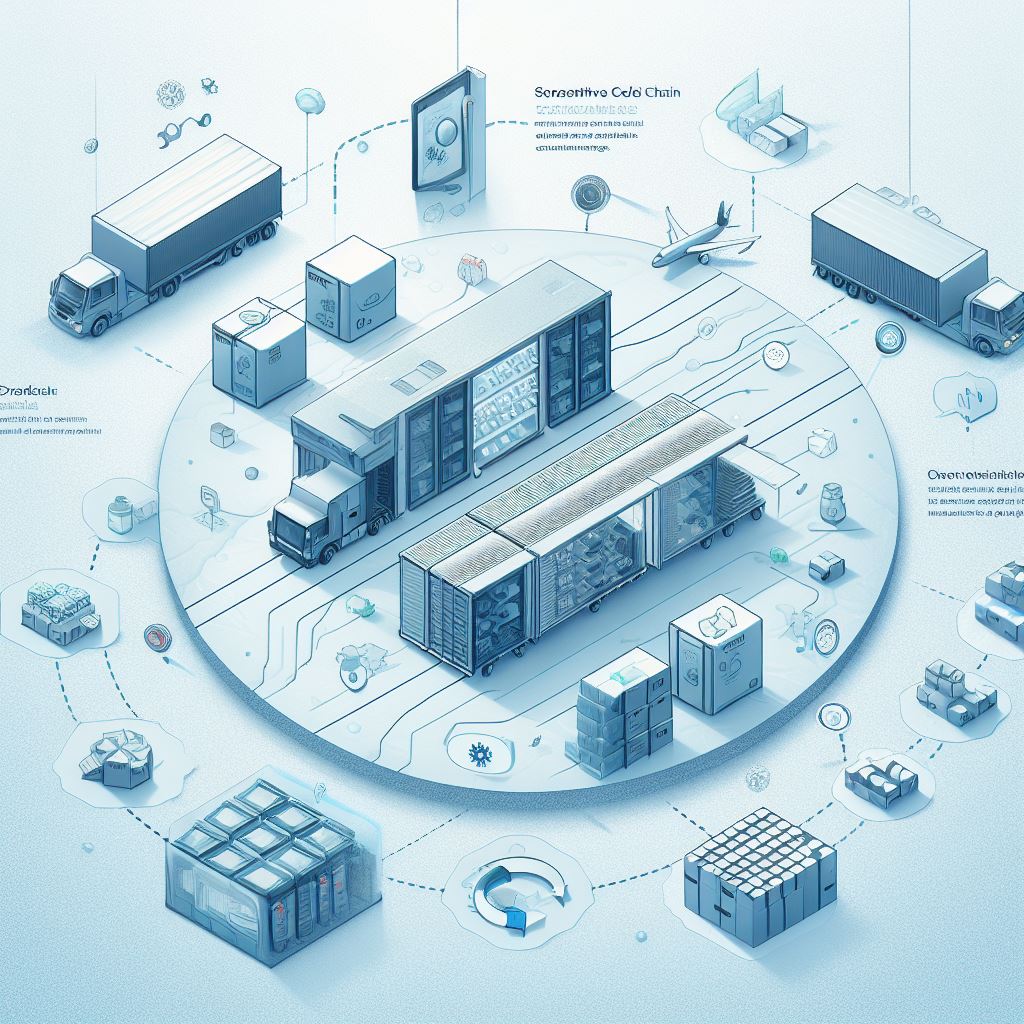

Revolutionizing Cold Chain Operations: Mastering Efficiency

Unveiling the Secrets to Perfect Perishable Compliance

Revolutionizing Container Shipping: Data Loggers Ensure Freshness

Revolutionary Temperature Data Loggers Transform Industries

Cold Chain Risks: Safeguarding Global Supply Chains

Proper Positioning of Temperature Probe

One important step in mastering temperature data logging is ensuring proper positioning of the temperature probe. Positioning accuracy and temperature probe maintenance are key factors in obtaining accurate and reliable temperature data. To achieve optimal results, consider the following guidelines:

- Choose a location that accurately represents the temperature of the environment or appliance being monitored.

- Avoid placing the probe in areas where temperature can fluctuate inadvertently, such as near heat sources or air vents.

- Ensure that the temperature probe is securely fixed in place to prevent movement or displacement.

- Regularly inspect and clean the temperature probe to remove any debris or contaminants that may affect its performance.

Testing Temperature Sensor Alarm

Regularly testing the functionality of temperature sensor alarms is essential for maintaining an effective temperature monitoring system. By conducting regular tests, we can ensure that the alarms are functioning properly and will alert us in case of any temperature deviations. This is crucial for preventing any potential damage or loss of temperature-sensitive products.

When troubleshooting temperature sensors, it’s important to optimize data analysis to identify any issues or abnormalities in the temperature readings. This can be done by comparing the sensor data with known reference points or conducting calibration tests.

Regular Review of Monitoring System

To ensure optimal performance of the temperature monitoring system, I consistently review its functionality and condition. Regularly scheduling checks and evaluations of the system is essential in maintaining accuracy and reliability. Here are four key reasons why this practice is crucial:

- Identify Technical Issues: Regular reviews allow me to detect any technical problems or malfunctions in the temperature logger and sensor. This enables me to address these issues promptly, ensuring that the system operates effectively.

- Verify Setup Accuracy: By conducting regular reviews, I can verify that all the settings and configurations, including the sample rate, are correct. This ensures that the system is accurately recording and monitoring temperature data.

- Maintain Effective Notifications: Regularly reviewing the monitoring system allows me to ensure that the notifications are set up properly. Effective notifications are essential for immediate response and timely action in case of any temperature abnormalities.

- Preserve System Effectiveness: By consistently reviewing the monitoring system, I can maintain its effectiveness over time. This includes addressing any potential issues promptly and making necessary adjustments to maximize performance.

Maintaining Accuracy and Reliability

Maintaining accuracy and reliability of the temperature monitoring system is crucial for optimal performance. In order to achieve this, it’s important to emphasize the importance of data analysis and troubleshooting common issues.

Data analysis allows for a comprehensive understanding of temperature trends and patterns, enabling the identification of potential problems before they escalate. By analyzing the collected data, it becomes possible to optimize the system’s performance and ensure accurate temperature monitoring.

Troubleshooting common issues is also essential to maintain accuracy and reliability. This involves regularly testing the functionality of alarms, fixing any issues immediately, and conducting regular reviews of the entire temperature monitoring system.