As a meat industry professional, I’ve seen firsthand the challenges of preserving quality and safety during transportation. That’s why I’m thrilled to share the groundbreaking advancements in active tracking that are revolutionizing meat shelf-life.

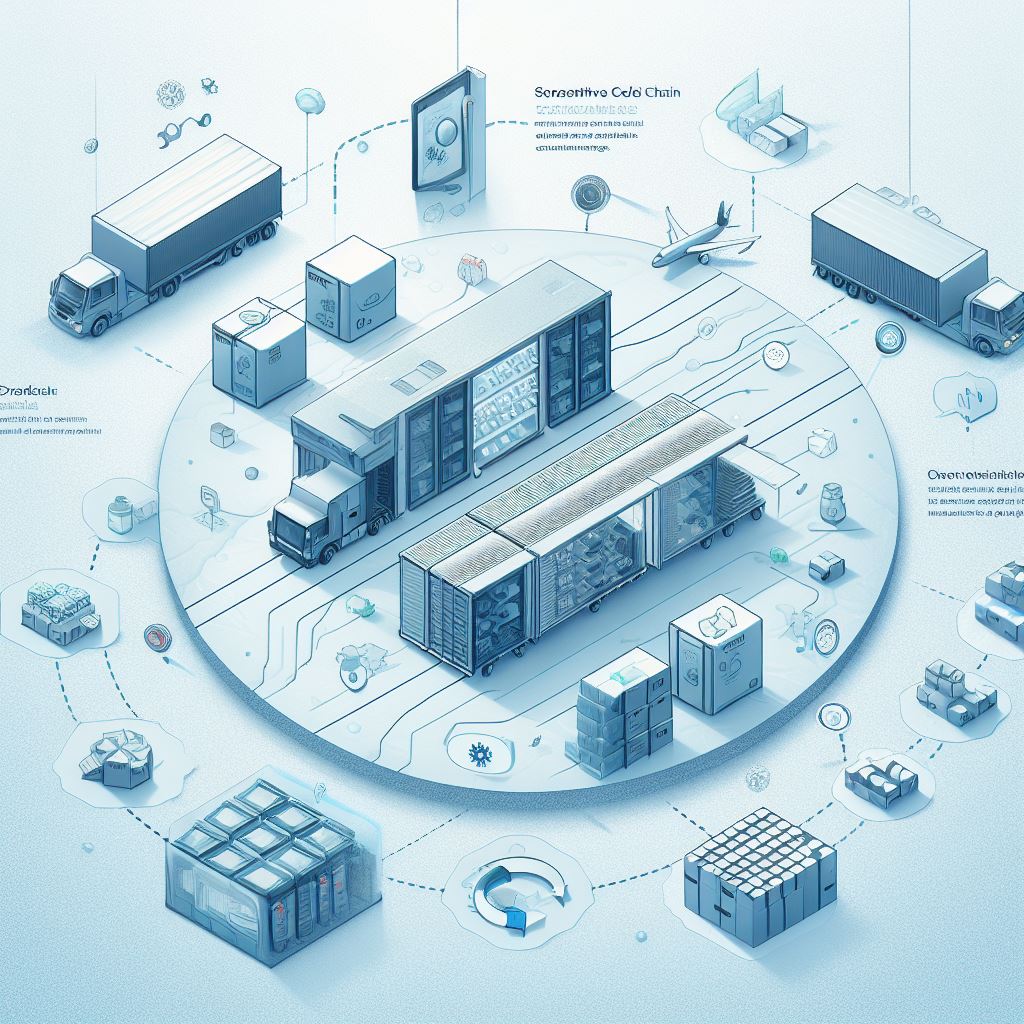

With real-time data collection and analysis, active tracking provides unprecedented visibility into temperature variations and product conditions. By maintaining optimal conditions throughout transit, this technology ensures meat stays fresh, tasty, and long-lasting.

Join me as we explore the exciting world of active tracking and its impact on meat quality.

Benefits of Active Tracking in Meat Industry

Active tracking in the meat industry provides significant advantages in terms of quality control and waste reduction.

The role of active tracking in reducing meat waste is crucial for ensuring that products remain fresh and safe for consumption. By using advanced technologies and real-time data collection, active tracking enables stakeholders to closely monitor temperature variations and product conditions throughout the supply chain. This allows for immediate corrective actions to be taken in case of breaches in temperature conditions, minimizing the risk of spoilage and contamination.

Additionally, the impact of active tracking on supply chain efficiency is undeniable. Real-time monitoring and data-driven decision-making contribute to a more streamlined and optimized meat supply chain, reducing waste and increasing product availability.

Role of Cold Chain Management in Meat Shelf-Life

Implementing cold chain management is essential for maximizing the shelf-life of meat products.

Temperature control plays a critical role in meat storage, as even slight temperature variations can lead to spoilage and contamination.

To improve meat shelf life through cold chain management, the following strategies can be implemented:

- Strict temperature control: Maintaining consistent temperatures throughout the supply chain is crucial for preserving meat quality and extending shelf-life. This can be achieved by using temperature-controlled storage facilities, refrigerated transport, and real-time temperature monitoring.

- Proper handling and packaging: Meat products should be handled and packaged in a way that minimizes exposure to temperature fluctuations and potential contaminants. Vacuum-sealed packaging and insulated containers can help maintain optimal conditions.

How Active Tracking Enhances Meat Quality

By utilizing active tracking technologies, I can attest that the quality of meat can be significantly enhanced throughout the entire supply chain. Active tracking plays a crucial role in improving supply chain efficiency and ensuring food safety.

With real-time monitoring and data-driven decision-making, active tracking enables stakeholders to identify deviations from the optimal temperature range and take immediate corrective actions. This ensures that temperature-sensitive meat products are handled properly from production to consumption, maintaining their freshness and safety.

Active tracking also minimizes waste and optimizes resources in the meat industry, contributing to a more sustainable and efficient supply chain. By replacing spoilage with sustainability and loss with resource optimization, active tracking enhances the overall quality and marketability of meat products, meeting consumer expectations for high-quality, safe, and fresh meat.

Extending Shelf-Life of Cultured Meat

To extend the shelf-life of cultured meat, it’s essential to implement innovative active tracking technologies. These technologies play a crucial role in improving sustainability and reducing waste in the meat industry.

Here are two key benefits of active tracking in extending the shelf-life of cultured meat:

- Minimizing waste: Active tracking provides real-time data collection and analysis, allowing stakeholders to monitor temperature variations and product condition. By ensuring that cultured meat products are maintained under optimal conditions during transit, active tracking minimizes waste and extends the freshness and longevity of the meat.

- Optimizing resources: Through active tracking, stakeholders gain unprecedented visibility over the freshness, taste, and quality of cultured meat products. This visibility enables them to make data-driven decisions, optimizing resources and ensuring that the meat maintains its quality and safety throughout the supply chain.

Read More:

Terms And Conditions

Privacy Policy

Revolutionary Track & Trace Solutions Protect Pharmaceutical Integrity

Mastering Temperature Data Logging for Optimal Performance

Unveiling the Secrets to Perfect Perishable Compliance

Advantages of Real-Time Temperature Monitoring

Real-time temperature monitoring offers valuable benefits for ensuring the quality and safety of meat products in the food industry. By implementing real-time monitoring systems, such as active tracking, businesses can have immediate updates on temperature variations throughout the supply chain. This level of visibility enhances quality control and enables timely interventions when necessary, improving overall product management.

Real-time temperature monitoring directly impacts the taste, texture, and appearance of meat products, ensuring they remain at peak freshness. By focusing on quality, businesses can strengthen their brand’s reputation and meet consumer expectations for high-quality meat.

Additionally, real-time temperature monitoring provides visibility into other crucial metrics like location and exposure, enabling businesses to optimize supply chain efficiency. It also enables predictive maintenance, allowing potential equipment failures or deviations to be foreseen and addressed, preventing disruptions and maintaining a seamless supply chain.